ESN: How it’s made

Have you ever wondered how Nutrien creates ESN Smart Nitrogen? After more than 20 years on the market, you’ve likely seen what has become known as the “ESN green” granules. For the first time, we’re taking you behind the scenes to learn where and how they’re made. Watch the video above for a look at the patented process or read through the details below.

Nutrien has two facilities that create Environmentally Smart Nitrogen in North America: one in Alberta, Canada and one in Missouri, USA. The Canadian facility currently has the capacity to produce more than 200,000 metric tons per year, which is 220,460 short tons; and the US facility has the capacity to produce approximately 220,000 metric tons, which is 260,000 short tons.

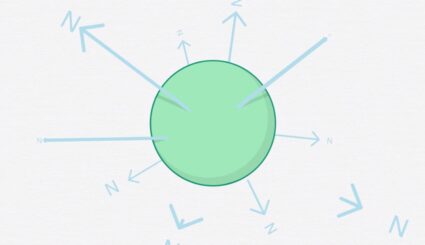

The Environmentally Smart Nitrogen, or ‘ESN,’ produced at these facilities is urea comprised of 44% nitrogen, contained in a unique, flexible polymer coating that protects the nitrogen from common loss mechanisms. The polymer membrane allows moisture to diffuse into the granule, creating a nitrogen solution. This solution moves out through the membrane at a rate that is controlled by soil temperature, allowing it to more closely match the nitrogen demand of the growing crop than conventional applications. Through this process, ESN gives crops nitrogen when they need it.

ESN is produced through a sophisticated, patented process. Production begins by bringing urea into the ESN plant with a series of belts and weight-ometers. The urea is warmed to a temperature that supports the chemical reaction needed to add the proprietary coating. The product travels into a coating reactor where it passes through a series of chemical application nozzles that apply the ingredients that create the coating. As it travels through the drum the coating increases in thickness to become stronger and more resilient.

Once coated sufficiently, it is cooled and allowed to cure. After cooling, it travels across a vibrating screen that only allows granules of the proper size and shape to make it through. This strictly controlled process assures ESN meets our size and uniformity index specifications, so that your crops get the most even distribution and nutrition possible.

Now that you know how ESN is made, learn about the life cycle of the ESN granule and how it works.

Questions or comments? Find us on Twitter @SmartNitrogen.